Scan smarter, Stay safer.

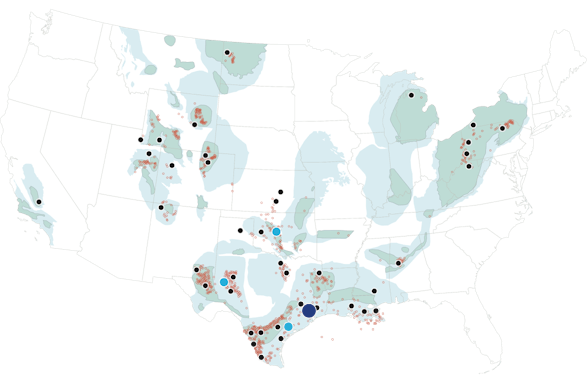

Maximize the value of your natural gas compression while minimizing your methane emissions with Ecotec.

Easy to use and built for daily field use at Ecotec devices combine compact portability with laser-precision that empowers operators to rapidly find and fix methane leaks.

With Ecotec, you can put reliable, easy-to-use methane leak detection into the hands of every operator—helping your teams stay safe, reduce emissions, and maximize operational efficiency, one scan at a time.

From pinpoint scans to post-repair checks, Ecotec gives you a reliable suite of tools for daily methane emissions control and safety assurance.